Category

- Titanium Fasteners

- Titanium Racing Parts

- Titanium Machined Parts

- Titanium Material

- Titanium Screws

- Titanium Bolts

- Titanium Nuts

- Titanium Washers

- Titanium Pins

- Titanium Bicycle Parts

- Titanium Motorcycle Parts

- Titanium Auto Parts

- Custom Titanium Machined Parts

- Titanium Tools

- Titanium Bars

- Titanium Sheets

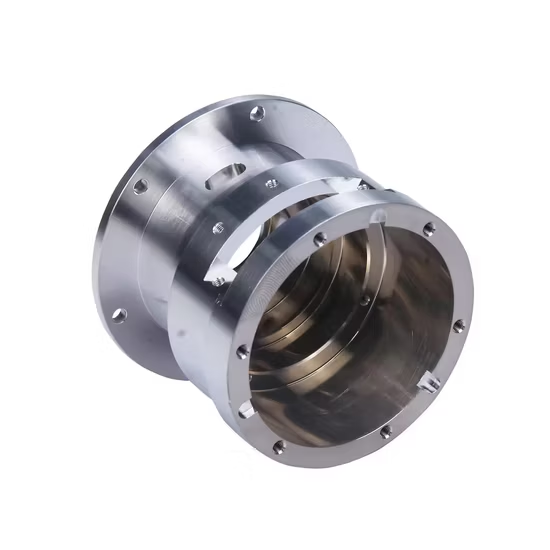

Custom Precision Machining CNC 5 Axis Medical Machined Titanium Surgical CNC Machined Parts

1. Part Name: Custom Precision Machining CNC 5 Axis Medical Machined Titanium Surgical CNC Machined Parts 2. Parts Param

Basic Info

| Model NO. | MJT00278 |

| Application | Fastener, Auto and Motorcycle Accessory, Hardware Tool |

| Standard | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME |

| Surface Treatment | Painting /Anodizing/Passivating/Zin Plating |

| Production Type | Single Production |

| Machining Method | CNC Machining |

| Material | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron |

| Processing Method | CNC Turning + CNC Machining |

| Materials Available | Nylon/ Stainless Steel / Aluminum /Brass/Iron |

| Tolerance | +/- 0.005 mm |

| Quality Control | 100% Full Inspection |

| Product Delivery | Based on Your Qty |

| Surface Treatment Available | Anodizing, Electroplated,Coating |

| Certificates | ISO 9001:2008 |

| Color | Any Color |

| Advantage | No MOQ+Delivery on Time |

| Verticality | +/-0.005 |

| Parallelism | +/-0.05 |

| Accuracy of Machining | +/-0.005 mm |

| Surface Roughness | Ra 0.8 |

| Concentricity | 0.003 |

| Package | Box, Wood Crate, Rust Prevention |

| Transport Package | Carton with Foam |

| Specification | 80*120*200 |

| Trademark | MJT |

| Origin | Dongguan China |

| HS Code | 8487900000 |

| Production Capacity | 500000/ Year |

Product Description

1. Part Name:Custom Precision Machining CNC 5 Axis Medical Machined Titanium Surgical CNC Machined Parts

2. Parts Parameter| Process Technology | Workable size | Tolerance |

| CNC Turning | Φ0.5 - φ300 * 750 mm | +/-0.003 mm |

| CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.01 mm |

| Drawing Format | IGS, STP, X_T, DXF, DWG, PRO/E, PDF | |

| Test Equipment | Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

3. Material Available:

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 etc. |

| Copper | C11000, C12000, C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

3.Surface Treatment Available

| Zinc plating, Chrome plating, Nickel plating, Tin plating, Polishing, Anodizing, Power-coating, Oxide black, Sandblast Anodizing, Electroless nickel, Fe/Zn8/C PER ISO 2081, etc. |

4.Our Main Production & Inspection Equipments:

MARCHTON has 3, 4, and 5 axis CNC machining centers , CNC lathes, precision CNC milling machine, grinding machine, wire cutting, EDM machine, spectrometer, electronic altimeter, CMM etc. More than 50 sets of machine and testing equipment

5. Our Advantages:

1. 10 years more experienced engineers team and well trained sales team to support every project 2. Long term cooperation is our target, quality and price are our basic to achieve it. 3. Provide different shipping way quotes to customer, accordingly customer accepted delivery time to find cheapest shipping way. 4. Well organized and clean workshop environment for all employees6. Package & Shipping: 1. Well packed wooden box for the best protection during transportation from our door to the customer's door

2. Small MOQ orders, we protect your parts in transportation as Soft paper\cardboard\bubble bag etc + Harden cartons + Foam

8. FAQ:

1) Are you a factory or a trade company?We are manufacture, so we can offer you the competitive price and fast lead time. Welcome to visit out factory.2) Can you provide some samples?Yes. Samples can be provided. You just need to bear some sample cost and we'll return it back when proceed into mass production.3) Will my drawing be safe after you get it? Yes. We will not release your design to the third party without your permission.4) How to deal with the parts received when they are found to be in poor quality?Please rest assured that all our products are QC 100% inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non-conformance, please contact us immediately, take some pictures, we will check the problems and have them reworked or repaired at the first time. The resulting transportation costs are borne by our company.

9. Why Choose Us:

1. Quick quotation according to technical drawing2. Professional in developing ,manufacturing & stamping3. Provide the sample for your reference4. High quality with competitive price5. Work safety control and precision testing